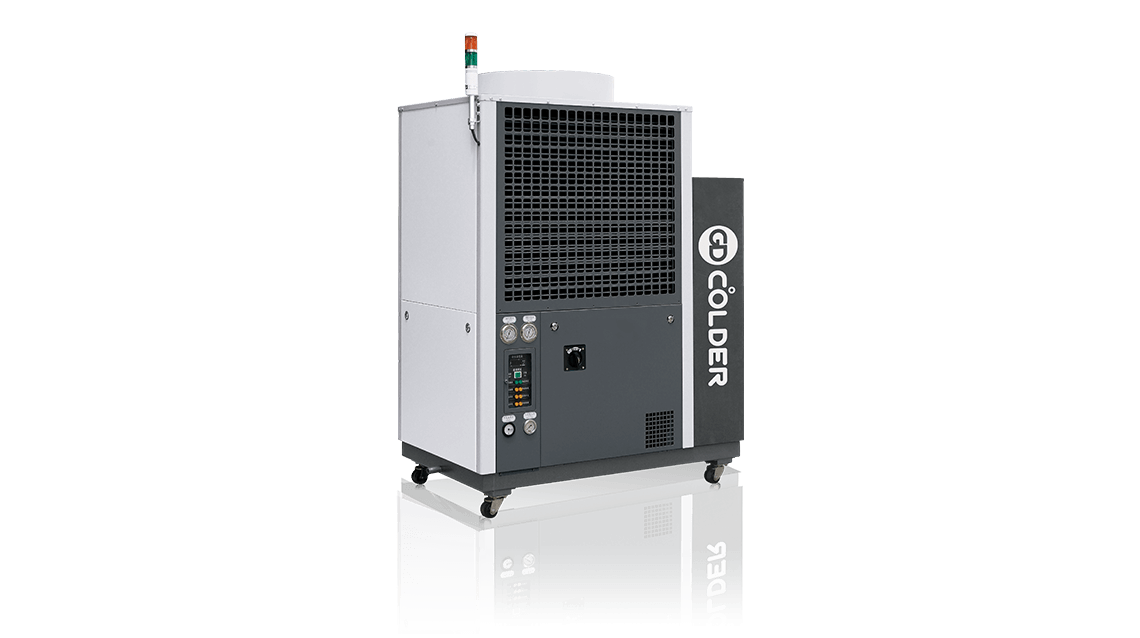

Air cooled chiller

AT-120A, 180A

Air-cooled engines rely on the circulation of air directly over heat dissipation fins or hot areas of the engine to cool them in order to keep the engine within operating temperatures.

High inductive electronic temperature control switch, and water pump, easy control the manu-facturing process liquid temperature(accuracy ± 0.5°C)

| Temp. Range | 5~40°C (Indoor) |

|---|---|

| Humidity Range | 40~80% |

| Cooling Capacity | 28~47 KW |

We Solve the Problem for Extra Heat from the Machine.

An Air Cooled Chillers For You

Industrial Solutions For Cooling And Thermoregulation

Air Cooled Chillers

Model / Specification

Explore More Solutions

Do You Know what Your solutions are for Cooling and Temperature ?

GD COLDER also provides you professional management of cold and warm temperature control, custom-made service and centralized cooling system.

Contact Now!

Industrial Application