A Paradigm shift in the Semiconductor Industry

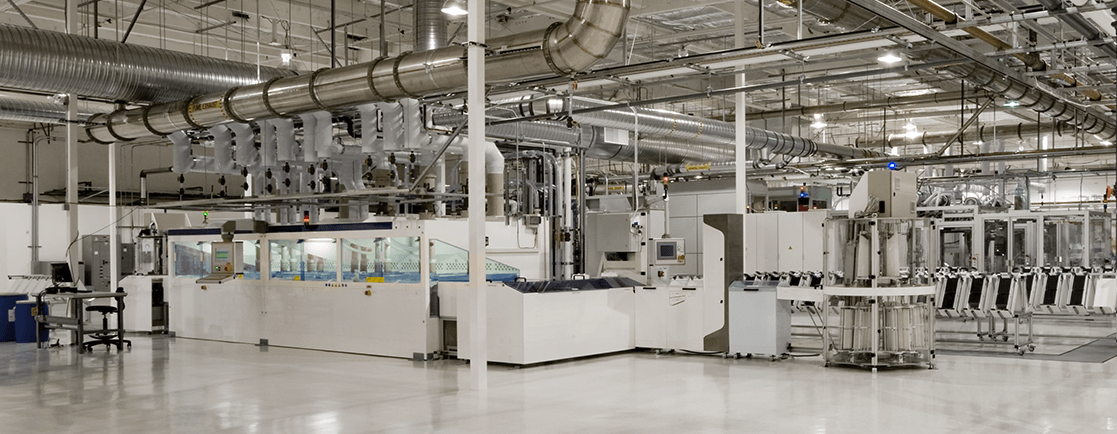

In the semiconductor industry, precise temperature control is critical for ensuring the reliability and performance of semiconductor manufacturing processes. Air cooled chillers and water cooled chillers are integral components of the cooling systems used in semiconductor fabrication facilities. This article explores the diverse applications of both types of chillers in the semiconductor industry, highlighting their importance and benefits in maintaining optimal operating conditions for semiconductor manufacturing.

Air Cooled Chillers:

Air cooled chillers are refrigeration systems designed to remove heat from a process using ambient air. They consist of components such as compressors, condensers, expansion valves, and evaporators, with air serving as the cooling medium. Air cooled chillers are commonly utilized in semiconductor manufacturing facilities for various applications due to their versatility and efficiency.

Applications in the Semiconductor Industry:

Cleanroom Cooling: Semiconductor fabrication facilities maintain cleanroom environments with controlled temperature and humidity levels. Air cooled chillers provide cooling for cleanroom air handling units (AHUs) to maintain the desired environmental conditions essential for semiconductor manufacturing processes.

Equipment Cooling: Semiconductor manufacturing equipment, such as etchers, deposition tools, and lithography systems, generate heat during operation. Air cooled chillers are used to dissipate heat from these equipment components, ensuring optimal operating temperatures and preventing overheating that could compromise semiconductor production.

Gas and Chemical Delivery Systems: Precise temperature control is essential for the safe and efficient operation of gas and chemical delivery systems in semiconductor fabrication. Air cooled chillers are employed to maintain the temperature of process gases and chemicals within specified ranges, ensuring their stability and integrity throughout the manufacturing process.

Advantages of Air Cooled Chillers:

Space Efficiency: Air cooled chillers do not require additional water sources or cooling towers, making them suitable for semiconductor facilities with limited space.

Energy Efficiency: Air cooled chillers utilize ambient air for cooling, eliminating the need for water consumption associated with water cooled systems and reducing overall energy consumption.

Easy Installation and Maintenance: Air cooled chillers are relatively easy to install and require minimal maintenance compared to water cooled systems, resulting in cost savings and operational efficiency for semiconductor manufacturers.

Water Cooled Chillers:

Water cooled chillers utilize water as the primary cooling medium to dissipate heat from industrial processes. These chillers are composed of components similar to air cooled systems, including compressors, condensers, expansion valves, and evaporators. Water cooled chillers are widely employed in the semiconductor industry for applications that demand high cooling capacities and precise temperature control.

Applications in the Semiconductor Industry:

Semiconductor Wafer Fabrication: Water cooled chillers play a crucial role in maintaining the temperature of process cooling water used in semiconductor wafer fabrication processes, including etching, deposition, and cleaning steps. Precise temperature control is essential for achieving uniform etching and deposition rates, ensuring the quality and consistency of semiconductor devices.

Thermal Management of Equipment: Semiconductor manufacturing equipment, such as plasma etchers and chemical vapor deposition (CVD) systems, require precise thermal management to maintain stable operating conditions. Water cooled chillers provide efficient cooling for heat-generating equipment components, preventing overheating and ensuring optimal performance and reliability.

Laser Systems: Laser technologies are integral to various semiconductor manufacturing processes, including photolithography and wafer inspection. Water cooled chillers are utilized to maintain the temperature of laser systems, ensuring stable laser output and minimizing thermal drift that could affect semiconductor device accuracy and yield.

Advantages of Water Cooled Chillers:

High Cooling Capacity: Water cooled chillers offer higher cooling capacities compared to air cooled systems, making them suitable for semiconductor manufacturing processes with substantial heat loads.

Superior Heat Transfer: Water has a higher heat transfer coefficient than air, allowing water cooled chillers to provide more efficient cooling and precise temperature control, critical for semiconductor fabrication.

Quiet Operation: Water cooled chillers operate more quietly than air cooled systems, minimizing noise levels in semiconductor facilities and contributing to a conducive working environment for operators.

Conclusion:

In the semiconductor industry, both air cooled chillers and water cooled chillers play essential roles in maintaining precise temperature control and ensuring the reliability and efficiency of semiconductor manufacturing processes. While air cooled chillers offer advantages in space efficiency and ease of installation, water cooled chillers excel in providing high cooling capacities and superior heat transfer capabilities. Semiconductor manufacturers must carefully evaluate their specific requirements and operational needs to determine the most suitable chiller solution for their facilities, ultimately optimizing production performance and enhancing semiconductor device quality and yield.

Customized Solutions for your Business.

We Solve the Problem fo Extra Heat from the Machine.