A Paradigm shift in the Centralized Cooling System

Centralized cooling systems are essential in various industries, providing efficient cooling solutions for large-scale operations. Among the key components of these systems are air cooled chillers and water cooled chillers, which play crucial roles in maintaining optimal temperatures for processes and equipment. This article delves into the functions of air cooled chillers and water cooled chillers in centralized cooling systems and discusses their planning and implementation.

1. Understanding Air Cooled Chillers and Water Cooled Chillers

Air cooled chillers and water cooled chillers are both types of refrigeration systems used for cooling purposes. The main difference lies in the method they use to dissipate heat:

Air Cooled Chillers: These systems utilize ambient air to remove heat from the refrigerant. They consist of components such as compressors, condensers, expansion valves, and evaporators. Air cooled chillers are suitable for applications where water availability or quality is limited, or where space constraints exist.

Water Cooled Chillers: In contrast, water cooled chillers use water as the primary cooling medium. They also consist of similar components as air cooled chillers but rely on a constant water supply for operation. Water cooled chillers are preferred for applications requiring precise temperature control and high cooling capacities.

2. Roles in Centralized Cooling Systems

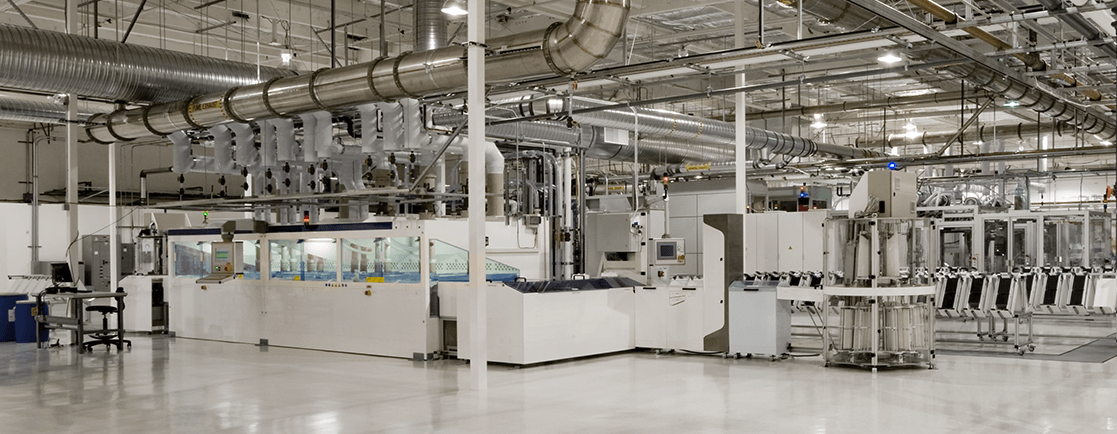

Centralized cooling systems integrate multiple chillers to provide cooling to various processes and equipment within a facility. Both air cooled chillers and water cooled chillers play critical roles in these systems:

Air Cooled Chillers: These chillers are often employed in centralized cooling systems for facilities where water availability is limited or where outdoor installation is preferred. They are suitable for cooling smaller-scale operations or serving as supplementary units in conjunction with water cooled chillers.

Water Cooled Chillers: Water cooled chillers are the primary workhorses in centralized cooling systems, especially in large industrial settings. They offer higher cooling capacities and more precise temperature control, making them ideal for cooling heavy-duty equipment and processes.

3. Planning a Centralized Cooling System

Designing and planning a centralized cooling system requires careful consideration of various factors to ensure optimal performance and efficiency:

Load Calculation: Determine the cooling load requirements of the facility by assessing the heat generated by equipment and processes. This calculation helps in sizing the chillers appropriately to meet the cooling demands.

Chiller Selection: Based on the cooling load calculation, choose the appropriate mix of air cooled chillers and water cooled chillers. Consider factors such as space availability, energy efficiency, and maintenance requirements.

System Layout: Design the layout of the centralized cooling system, considering factors such as piping, electrical connections, and accessibility for maintenance. Ensure proper spacing between chillers and other equipment to facilitate airflow and maintenance.

Integration with Building Management Systems (BMS): Integrate the cooling system with BMS for centralized monitoring and control. This allows for real-time monitoring of chiller performance, temperature regulation, and energy optimization.

Backup and Redundancy: Implement redundancy measures to ensure continuous cooling operation. This may involve installing backup chillers or incorporating fail-safe mechanisms to mitigate downtime in case of chiller failure.

Environmental Considerations: Consider environmental factors such as ambient temperature, humidity levels, and local regulations when planning the cooling system. Optimize chiller operation to minimize energy consumption and environmental impact.

Conclusion

Air cooled chillers and water cooled chillers are integral components of centralized cooling systems, providing efficient cooling solutions for various industrial applications. By understanding their roles and planning considerations, facility managers can design and implement centralized cooling systems that meet the specific requirements of their operations while ensuring optimal performance, energy efficiency, and reliability.

Customized Solutions for your Business.

We Solve the Problem fo Extra Heat from the Machine.